Disclosure: This post may contain affiliate links, meaning we get a commission if you decide to make a purchase through our links, at no cost to you. Please read our disclosure for more info.

Removing rust and paint from metal surfaces requires more than brute force. The right power tool accessories can dramatically reduce labor, improve safety, and deliver a smooth, clean surface ready for refinishing. This guide explores the most essential accessories, from abrasive wheels to polishing buffs, and offers tips for making a smart wire wheel selection for effective metal cleaning.

In This Post:

Why Accessory Choice Matters for Surface Prep

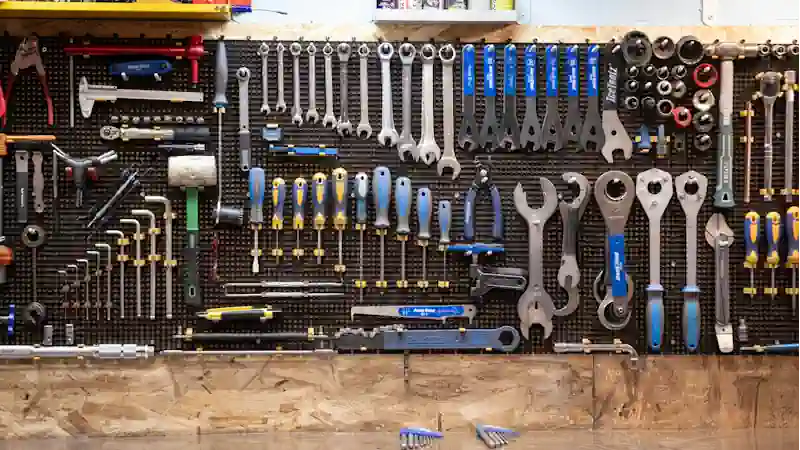

Power tools are only as effective as the accessories they use. When removing rust or paint, the goal is to strip away the surface without damaging the material underneath. Accessories like wire wheels, flap discs, and buffing pads are designed with this balance in mind.

The wrong accessory can gouge metal, leave swirl marks, or fail to remove all corrosion. That’s why understanding the differences in material, grit, and form is essential to successful surface preparation.

Wire Wheels: The Frontline Against Rust

Wire wheels are a go-to for rust and paint removal, especially on ferrous metals. They come in a variety of configurations, including crimped wire, knotted wire, and cup brushes. Each serves a unique purpose:

- Crimped Wire Wheels are ideal for light-duty cleaning and polishing.

- Knotted Wire Wheels offer aggressive cleaning for heavy rust and scale.

- Wire Cup Brushes work best on larger flat surfaces.

Choosing the right wire wheel can be the difference between a job well done and a damaged workpiece. For a deeper dive into how to choose the right wire wheel, this wire wheel selection for effective metal cleaning article provides a comprehensive breakdown.

Flap Discs and Sanding Attachments

Flap discs are another excellent accessory for rust and paint removal. Unlike traditional grinding wheels, flap discs consist of overlapping abrasive flaps that wear away gradually. This allows for more consistent performance and a smoother finish.

Key benefits of flap discs:

- Excellent for blending and smoothing after rust removal

- Available in a variety of grits and materials

- Safer than hard grinding wheels for softer metals

Ceramic and zirconia abrasives tend to perform best for stubborn coatings and corrosion, while aluminum oxide is more economical for general use.

Buffing Pads and Polishing Compounds

Once the rust and paint are removed, buffing pads and polishing compounds come into play. These accessories help bring metal to a shine and prepare it for paint, powder coating, or sealing. Buffing wheels are typically used with rotary tools or bench grinders.

Types of buffing products include:

- Cotton buffs for light polishing

- Sisal or treated cloth buffs for heavier cutting

- Loose sewn buffs for achieving a mirror finish

Pairing these with the right compound (e.g., tripoli, rouge, or white diamond) makes a significant difference in the final result. Using the wrong combination can burnish the surface or leave hazy marks.

For detailed guidance on this topic, the buffing products breakdown selecting the ideal polishing tools resource from Benchmark Abrasives walks you through compound and wheel pairing for different metals.

Safety Considerations

While these accessories boost efficiency and results, they also pose risks. Wire bristles can break off at high speeds, and sanding attachments can kick up fine particulate matter. Always use proper personal protective equipment (PPE), including:

- Safety goggles or a face shield

- Respirators or dust masks

- Gloves and long sleeves

According to the Occupational Safety and Health Administration (OSHA), PPE should be selected based on the potential hazards present during each phase of surface preparation. Adequate ventilation is also critical when working indoors.

Matching Tools and Surfaces

Surface material and condition play a huge role in selecting accessories:

- Steel surfaces with heavy rust need aggressive wire wheels or ceramic flap discs.

- Aluminum surfaces benefit from less aggressive options to avoid scratching.

- Painted wood may call for softer abrasive pads or sanding sponges.

Always test on a small, inconspicuous area first. And when working on painted items that may predate 1978, be aware of the potential for lead-based paint. The EPA guidelines for lead paint removal offer safety precautions for these cases.

Final Thoughts

Choosing the right accessories isn’t just about saving time—it’s about achieving professional-quality results. From making an informed wire wheel selection for effective metal cleaning to understanding the best buffing products for your project, smart decisions pay off in better finishes and longer-lasting restorations.

Understanding your material, the nature of the rust or paint, and the final surface you want to achieve will guide your tool and accessory choices. With the right combination in hand, even the most stubborn corrosion doesn’t stand a chance.